From this...

and this...

Fishy Filaments can do this...

Lifecycle of a Cornish Fishing Net from fishyfilaments on Vimeo.

and this...

Fishy Filaments can do this...

Lifecycle of a Cornish Fishing Net from fishyfilaments on Vimeo.

The Whys and Wherefores

The plastics contained in fishing nets have a value as a raw material, unfortunately the economics of the global recycling industry works against establishing a local-scale solution, and as a result we see the value of those nets exiting the county, or worse; going to landfill or being added to waste-to-energy streams.

Fishy Filaments wants to provide a local, commercial route to intercept and recycle marine plastics and by doing so capture the value of those materials for the local economy after their first life as fishing gear.

To this point the project has been self-financed, but has been working with the support of Fishing for Litter (South West) and The Newlyn Pier and Harbour Commissioners, with the aim of taking both caught marine litter (sometimes known as ghost gear) and end-of-life fishing nets, processing them locally and producing a valuable hi-tech material for the fast-growing 3D printing sector.

The project has already produced a world first; we made a 3D printed form made entirely from recycled fishing nets that were used by the Newlyn fleet and in the longer term we have plans to take other locally-arising wastes, produced by boat and board-building, to add further products to the portfolio.

The ultimate aim is to go into commercial production, securing supplies of used fishing gear from around the county, and maybe further, making local hires and selling the 3D printing filament to a national or possibly global market. For Fishy Filaments a sustainable business is one that is self-supporting as well as being socially and environmentally responsible.

However before we can get to that full commercial roll-out, there remains a phase of up-scaling and product testing that needs to be done. It is this advanced feasibility study that we are asking for help with.

To this point our Research and Development has been a well-thought through, but manual process able to produce only limited lengths of filament at a time. To get our product consistency high enough to justify sending the product to external testers, the R&D kit used so far needs to be replaced by lab grade production machinery.

The £5000 target is sufficient to buy the professional-quality equipment necessary to produce a testable product and construct demo pieces from that product. This feasibility study will also provide the numbers upon which a final business plan will be built before we enter a final round of ‘go live’ funding.

Technically we’ve proven the process. Now we need to prove that a business can be built on it.

Rewards

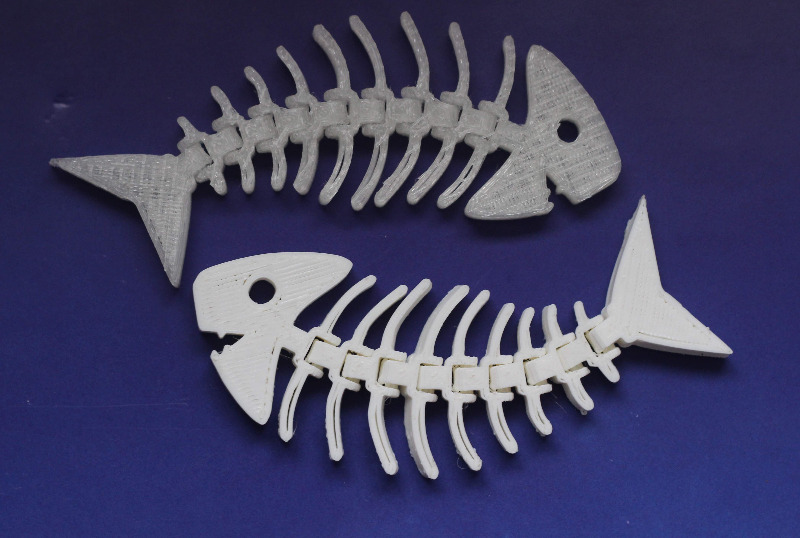

It is customary to offer rewards for funding pledges. Fishy Filaments is offering a range of pledge options, some of which include 3D printed plastic items.

These items were produced by Fishy Filaments in Cornwall using an open source design posted on Thingiverse by StevenDuval (http://www.thingiverse.com/thing:1360291) and are made from PLA, a biodegradable plastic whose raw materials are cornstarch or milk. We have conducted independent tests to confirm that the PLA used does degrade over time.Given the nature of the issues surrounding marine plastics we have also given pledgees the option to NOT recieve a plastic item, even one that we feel is appropriate, and we respect that choice.

These items were produced by Fishy Filaments in Cornwall using an open source design posted on Thingiverse by StevenDuval (http://www.thingiverse.com/thing:1360291) and are made from PLA, a biodegradable plastic whose raw materials are cornstarch or milk. We have conducted independent tests to confirm that the PLA used does degrade over time.Given the nature of the issues surrounding marine plastics we have also given pledgees the option to NOT recieve a plastic item, even one that we feel is appropriate, and we respect that choice.

Our rewards include;